Wherever there is industrial activity, compressed air is usually needed. Although electric actuators have replaced the traditional pneumatic applications in some cases, there are and always will be new applications for compressed air (such as in fish farming). Tamrotor is an OEM product provider for compressor and machine builders who use air ends and related components in their own manufactured compressors or compressed air systems onboard their equipment.

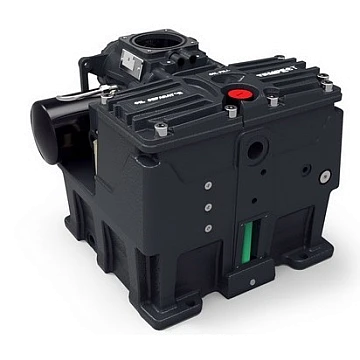

The basic idea is that Tamrotor supplies components to an OEM customer, who then builds a working compressor or compressed air application onboard. ENDURO air ends, TEMPEST integrated air ends or CT compressor packages are not capable of operating as such, but always require machine building to make them a part of a working compressor or compressed air system. For example, ENDURO air ends need a lot of building around them to become a working compressor. TEMPEST integrated air ends offer efficient and compact solutions for oil sump and separation from air with a residual oil content less than 3 mg/m3 in the air (aerosols), even in steep operational tilting angles. A CT package on the other hand, needs only the starter to become a working compressor. However, often CT customers also equip them with their own measuring sensors and so on. Since the Tamrotor OEM products cannot be used as such without integration, the OEM is always liable for their end product and that its documentation meets the industry standards, local laws and regulations. All Tamrotor OEM products are made in accordance to EC machinery directive.

Tamrotor is very strong in the following OEM customer segments:

- Industrial and portable compressor packagers / construction,

- Tunneling and rock drilling equipment manufacturers / train compressor manufacturers,

- CAFS fire-fighting equipment,

- heavy duty service vehicles, and

- off-shore.

Tamrotor products are based on a single-stage oil-injected screw compressor technology, which means that air is compressed in one stage from intake to discharge pressure. The oil is injected into the air end primarily to cool down the heat generated in the compression, seal the running clearances inside the air end (thus improving the efficiency), and lubricate the bearings through internal bores. Tamrotor OEM products are suitable for the pressure range 3-13 bar and air flow range 500 l / min - 74 m3 / min.