Lubricant is the lifeline of air compressor’s operation and performance. Synthetic lubricant is based on chemically synthesized polymers and contains numerous additives, offering superior antioxidant capacity, corrosion protection and wear resistance, with a notably long service life. Semi-synthetic lubricant, on the other hand, uses base oil derived from deeply hydrogenated mineral oils combined with some fully synthetic base oil. Its performance characteristics fall between traditional mineral oil and fully synthetic oil, offering improved performance over mineral oil while being more cost-effective than fully synthetic oil. For users with specific performance requirements for air compressors, seeking cost-effectiveness, or operating under non-continuous conditions, semi-synthetic lubricant is an ideal choice.

In this video, we will focus on Ingersoll Rand Ultra SL 4000 Screw Air Compressor High-End Semi-Synthetic Lubricant to explore its outstanding performance in depth. This product is carefully crafted from a blend of deeply hydrogenated refined III-class base oil and oil-soluble polyether V-class base oil, combined with a high-performance and balanced additive formula.

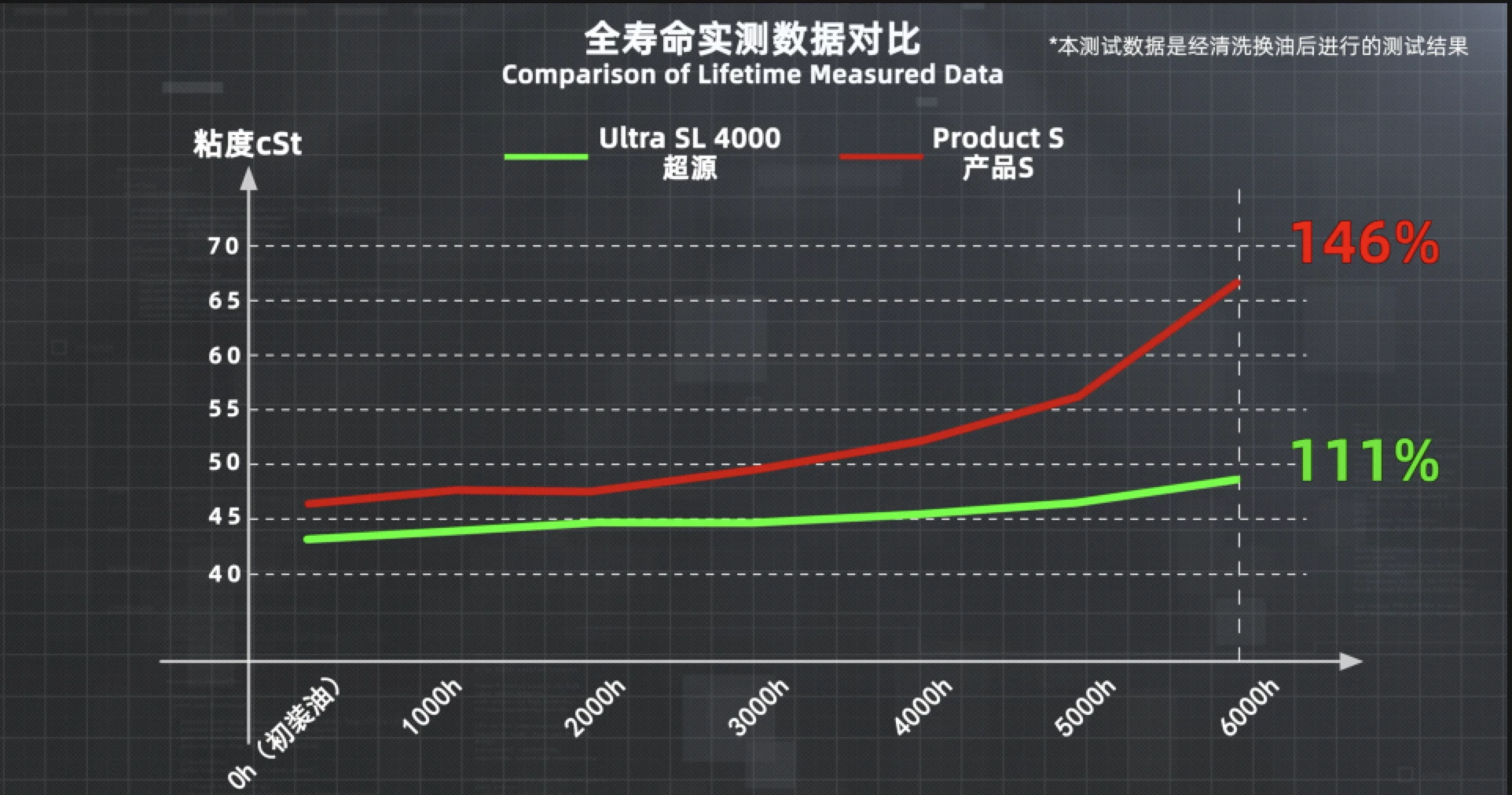

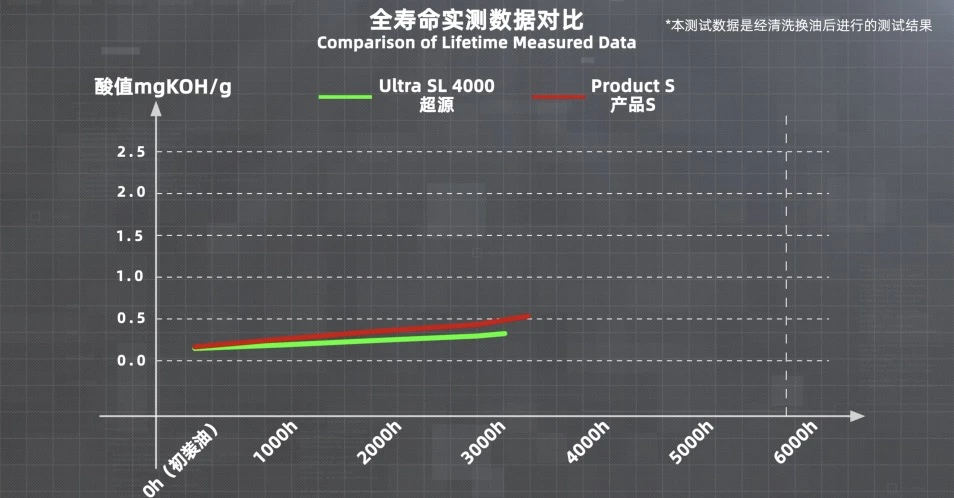

To clearly demonstrate the advantages of Ultra SL 4000 Lubricant, we have specially selected two representative semi-synthetic lubricants from the market for comparison. One is a commonly used semi-synthetic lubricant in China, abbreviated as Product C. The other is an international mainstream semi-synthetic lubricant, abbreviated as Product S. After rigorous testing in areas such as rust prevention, anti-foaming properties, cleaning performance, and full-life performance tracking, the results are clear and straightforward:

Rust prevention test: According to the ASTM D665B seawater corrosion test standard, the steel rod surface of product C was covered with rust spots, while the steel rods used for testing products S and Ultra SL 4000 Lubricant remained shiny, demonstrating outstanding rust prevention capability.

Anti-foaming test: According to the ASTM D892 foaming test standard, there was almost no difference between the initial foam height and the height after 10 minutes for Product C, Product S, and Ultra SL 4000 Lubricant. The defoaming performance of three products was comparable, all exceptionally well.

Cleaning test: Using an accelerated ageing TOST test, product C showed significant sludge accumulation, product S also produced a certain amount of sludge, while Ultra SL 4000 Lubricant showed almost no sludge. This is because Ultra SL 4000 Lubricant contains V-class polyether high-polarity base oil, which can effectively dissolve polar polymers, eliminating the possibility of coking and carbon deposits from the source, and further reducing the risk of high-temperature coking.